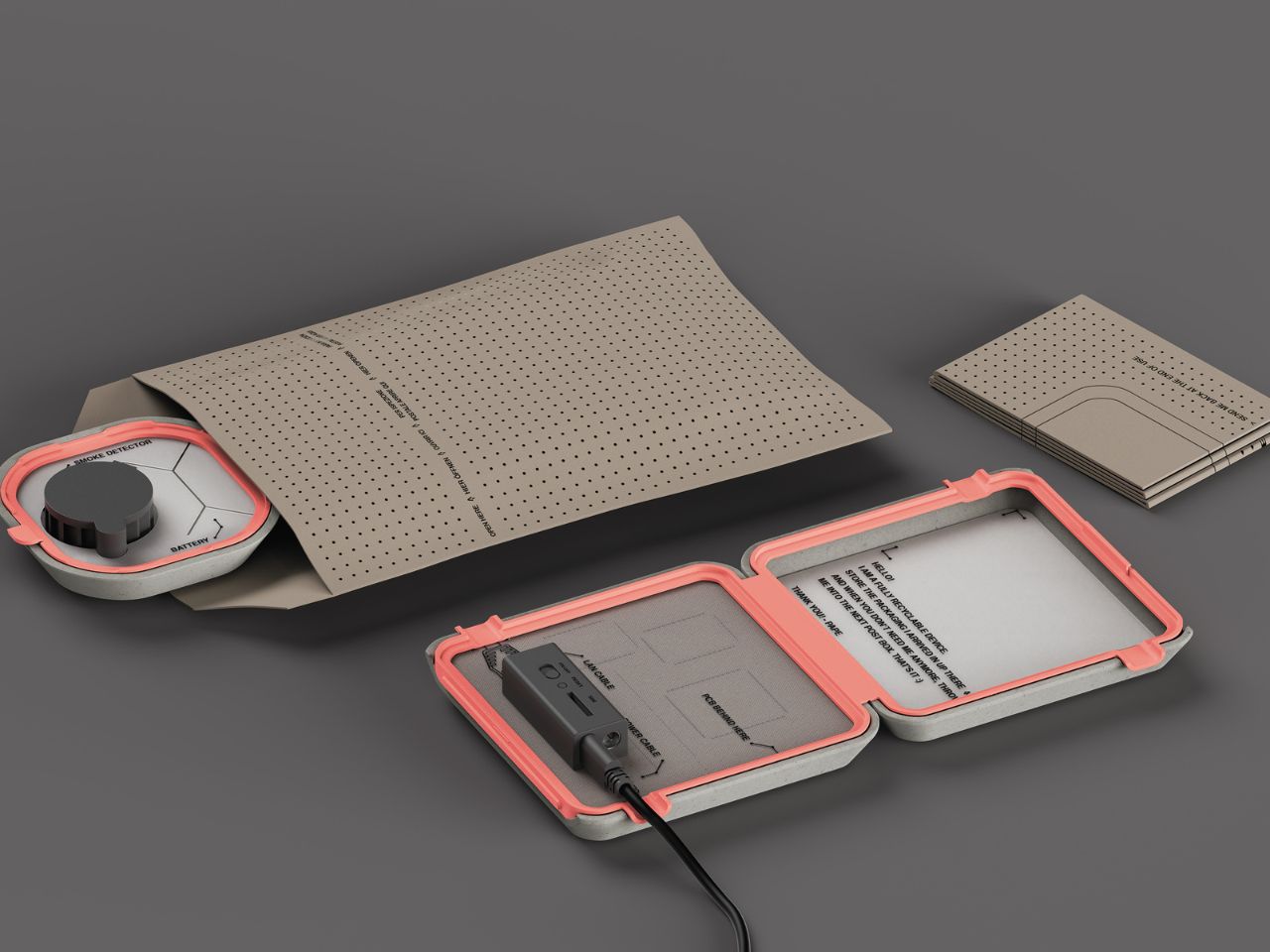

Imagine if your Wi-Fi router or smoke detector could completely dissolve at the end of its life, not into waste, but into a source for new products. This is the transformative idea behind PAPE, a groundbreaking product family redefining how we think about small electronics.

Crafted from densely pressed paper fibers and featuring a dissolvable, recyclable PCB board, PAPE doesn’t just aim to reduce e-waste, it eliminates it entirely. This innovative design creates a closed material cycle, making PAPE devices both environmentally friendly and cost-effective.

Designer: Franziska Kerber

Thanks to significant advancements in sustainable PCB-board technology, the electronics industry has made strides in developing dissolution processes for recycling. PAPE takes this progress to the next level by extending the dissolution process to the entire product, not just the PCB board.

Unlike traditional electronic devices that require mechanical deconstruction to separate components for recycling, PAPE’s design ensures that every part of the product can be recovered in a single step. The result? A system that’s more efficient, less wasteful, and remarkably user-friendly.

By focusing on affordability without compromising innovation, PAPE transforms sustainability into something accessible for everyday users. Its dissolvable materials and simple return system make responsible disposal easy and intuitive.

When you’re done using a PAPE device, you disassemble it just as you received it using its intuitive, hinged design and drop it into a postbox. From there, the manufacturer dissolves the entire product, recovering materials for reuse. This process eliminates the hassle of sorting or specialized drop-off points, making it simple for users to be part of the solution.

The beauty of PAPE lies in its holistic approach. Traditional small electronics rely on plastic housings and complex recycling methods that often fail to capture their full material value. These devices are prone to ending up in landfills or household trash, contributing to the 4.9 million tonnes of e-waste generated in Europe in 2020, much of which was never recycled.

PAPE addresses this issue by aligning the lifespan of its materials with the lifespan of its technology. Its paper-based housing ensures that the structural elements don’t outlive their usefulness, while the dissolvable PCB ensures that even the internal components are easy to recover. Together, these innovations create a product that is as kind to the planet as it is to the user.

What makes PAPE truly remarkable is its ability to combine cutting-edge material science with everyday practicality. By eliminating the need for mechanical deconstruction, it simplifies recycling while recovering more materials. It’s a true cradle-to-cradle solution for small electronics, a model for how the industry can transition to a circular economy.

The simplicity of the dissolution process doesn’t just make PAPE efficient; it makes it scalable. With the support of advancements in dissolvable PCBs and sustainable design, PAPE has the potential to revolutionize how electronics are made, used, and reborn.

PAPE isn’t just about creating better products—it’s about creating a better future. By rethinking how we approach e-waste and material recovery, PAPE sparks a vital conversation about sustainability in everyday life.

As the team looks to partner with PCB manufacturers and showcase PAPE’s potential through platforms like the James Dyson Award, the goal is clear: inspire change, foster innovation, and prove that sustainability doesn’t have to be a compromise.

PAPE challenges us to imagine a world where electronics never become waste. With its closed material cycle, user-friendly design, and pioneering dissolution process, it offers a vision of the future where every device serves as a stepping stone toward a more sustainable planet.

The post These Electronics Are Made Out Of Paper And Can Be Dissolved After Use That Helping End E-Waste Forever first appeared on Yanko Design.