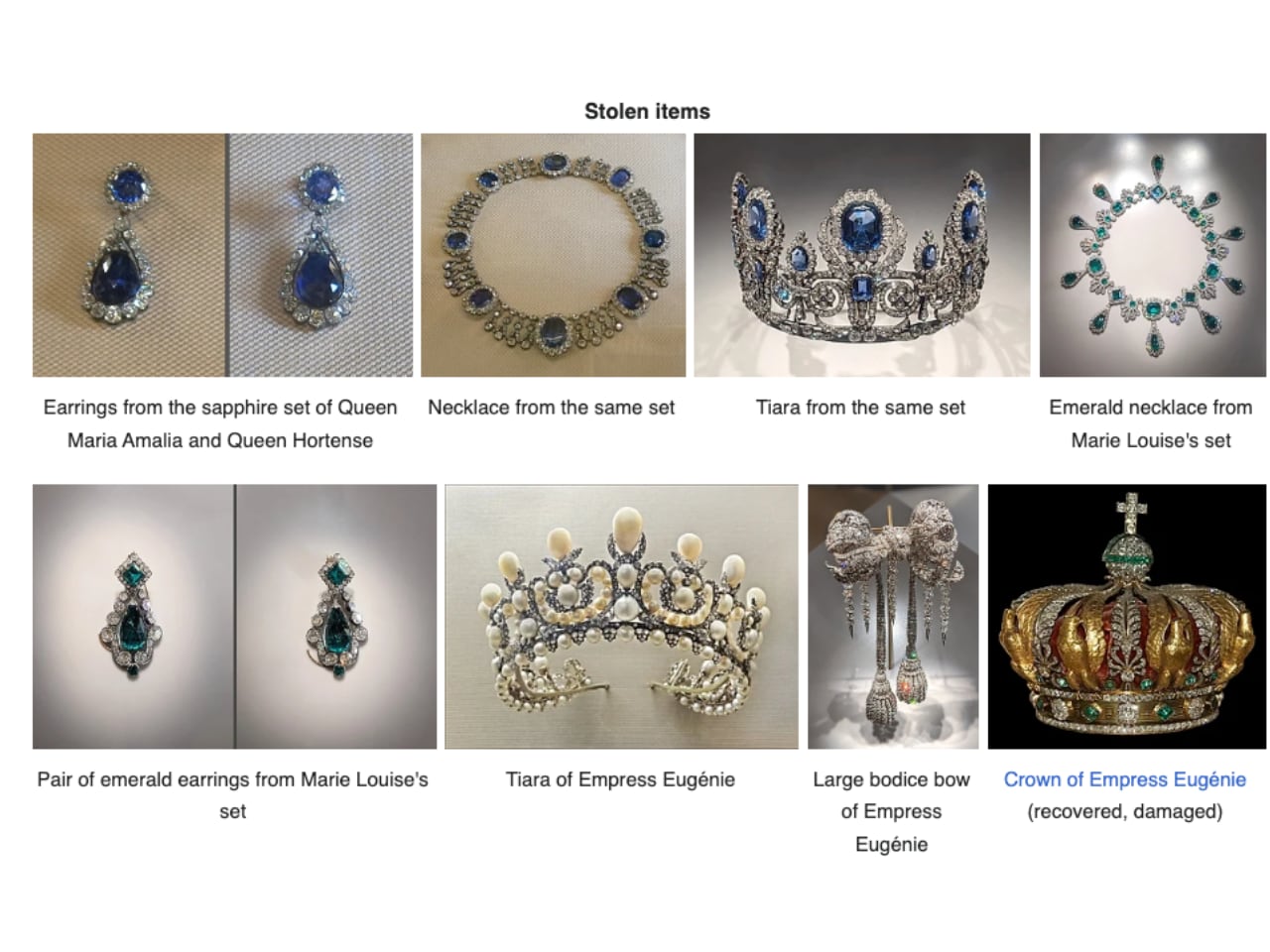

On October 19, 2025, professional thieves spent seven minutes in the Louvre’s Apollo Gallery. They used a crane to access an upper window, smashed two display cases, and escaped on motorcycles with eight priceless French crown jewels valued at $102 million. Paris prosecutor Laure Beccuau called the figure “spectacular” but noted it meant nothing compared to the historical loss.

What disappeared can’t be measured in gemstone value. These pieces preserved 215 years of jewelry engineering knowledge made physical. Every calculated proportion in the Marie-Louise emerald parure, every spring-mounted tremblant setting in Eugénie’s brooches, every articulated joint in the stolen diadems represented solutions to problems that took master craftsmen years to solve. When Étienne Nitot positioned 79 Colombian emeralds among 1,000 diamonds in 1810, he wasn’t decorating. He was engineering light behavior in candlelit ballrooms where diplomatic careers could pivot on whether an empress outshone her rivals.

Nitot’s Neoclassical Engineering: The Marie-Louise Parure

The stolen emerald necklace and earrings represent Napoleon’s 1810 commission to Nitot et Fils, his court jeweler and founder of what would become Chaumet. The emperor needed a diplomatic gift substantial enough to cement his Austrian alliance through marriage to Archduchess Marie-Louise. Nitot delivered a complete parure centered on Colombian emeralds that remain in the stolen pieces today, unlike the companion diadem (now at the Smithsonian) whose emeralds were replaced with turquoise in the 1950s.

The design vocabulary was political calculation. Scrolls and palmettes referenced Greco-Roman antiquity, positioning Napoleon as heir to classical emperors rather than another European monarch. Palmettes are stylized palm leaves appearing on Greek temples and Roman friezes. Nitot carved them in gold and silver, surrounding them with emerald medallions to create visual language that communicated imperial legitimacy without words.

The necklace demonstrates sophisticated gem hierarchy engineering. Nitot arranged emeralds in specific patterns among the diamond field, using size progression to control how viewers’ eyes moved across the piece. The deep green emeralds absorbed certain wavelengths while surrounding diamonds reflected others, creating calculated color contrast that enhanced both stone types. This wasn’t aesthetic preference. It was optical engineering executed in precious materials.

The metalwork reveals First Empire jewelry engineering at its peak. Nitot mounted gems on silver for the white metal’s superior light-reflecting properties, then backed the structure with gold for strength and tarnish resistance. This dual-metal approach let him use thinner silver elements than pure gold construction would allow, reducing weight while maintaining durability for extended wear during state ceremonies.

Diamond Cutting for Candlelight: Lost Optical Knowledge

The Marie-Louise pieces used rose-cut and old mine-cut diamonds exclusively. This was sophisticated optical engineering for pre-electric lighting, not historical limitation.

Rose-cut diamonds have flat bottoms and domed tops covered in triangular facets, typically 24 or fewer. Old mine-cut diamonds feature deeper profiles with larger facets and higher crowns than modern brilliant cuts. Both styles maximize light reflection in low, flickering candlelight rather than bright overhead illumination. A modern brilliant-cut diamond optimized for electric light would have appeared dull in the Tuileries Palace ballrooms where Marie-Louise wore these pieces. Nitot selected cutting styles that would make the necklace explode with light from candelabras positioned eight to twelve feet away at table height.

Each emerald’s placement factored in the viewing angles of seated dinner guests, standing reception attendees, and observers in gallery boxes above the ballroom floor. Nitot engineered three-dimensional light behavior, calculating how gems would appear from multiple elevations and distances simultaneously. This knowledge exists in the physical arrangement of stones, the precise angles of their settings, and the metalwork depths that controlled light reflection patterns. You cannot fully reconstruct it from photographs or descriptions.

The Sapphire Suite: Bourbon Restoration Design Language

The stolen sapphire diadem, necklace, and earring (one was left behind) belonged to Queens Marie-Amélie and Hortense, representing Bourbon Restoration and July Monarchy jewelry design from the early 19th century. These pieces demonstrate different design priorities than Napoleon’s neoclassical approach.

Sapphires set among diamonds create cooler color harmonies than emeralds, projecting restraint and established authority rather than imperial ambition. The geometric arrangements favored bilateral symmetry and repeating patterns that referenced hereditary legitimacy. Where Nitot’s work for Napoleon communicated “new empire,” the sapphire suite’s design language said “traditional monarchy.”

The metalwork featured extensive openwork, areas where backing metal was pierced or removed to maximize light flow through the gems. This technique required intuitive understanding of structural stress patterns. Master jewelers learned to identify where metal was structurally necessary and where it could be eliminated, reading how complex curved forms would flex during wear and reinforcing critical areas while piercing others.

The stolen pieces show openwork mastery. The metal forms delicate arabesques that appear impossibly thin, yet these pieces survived 150-plus years without structural failure. The jewelers achieved this through attention to grain direction in the metal, strategic reinforcement disguised as decorative details, and understanding how properly set gems contribute to structural stability.

Eugénie’s Engineering: The Stolen Brooches

The two stolen brooches from Empress Eugénie’s collection represent Second Empire jewelry design at its most technically ambitious. The large corsage-bow brooch contains 2,438 brilliant-cut diamonds plus 196 rose-cut diamonds in a single piece, requiring engineering solutions for mixed cutting styles.

Rose-cut stones need different setting depths than brilliant cuts. The jeweler had to vary the metalwork thickness to accommodate both styles while maintaining smooth curves across the brooch’s form. The bow motif wasn’t just decorative. It provided structural logic for distributing gem weight and managing stress points where the piece would flex during wear.

The reliquary brooch with 94 diamonds demonstrates another technical challenge: creating a hollow compartment for religious relics while maintaining structural integrity and gem security. The design required double-walled construction with the outer surface supporting diamond settings and the inner wall forming a sealed chamber. The two walls connected at strategic points that distributed weight without creating visible distortions in the outer surface.

En Tremblant Settings: Spring-Mounted Mystery

Several stolen pieces featured en tremblant settings, spring-mounted gem holders designed to make stones shimmer with subtle movement. The engineering is deceptively simple in concept: mount a gemstone on a thin metal spring that allows independent vibration. The execution is extraordinarily difficult.

The spring must be strong enough to return the gem to its original position after movement, but flexible enough to respond to breathing or slight head turns. Too stiff and the gem never moves. Too flexible and it wobbles chaotically or breaks. Master jewelers guarded their spring formulas and mounting techniques. The exact metal alloys, spring dimensions, and attachment methods varied between workshops and were rarely documented.

The stolen pieces contained dozens of these settings. Each one preserved specific knowledge about metal behavior, spring dynamics, and gem weight distribution that can only be studied through physical examples. The best en tremblant work remains mysterious because the craftsman’s hand was so skilled that construction evidence disappears into seamless execution.

Detachable Design: Engineering Versatility

French crown jewels often featured detachable elements allowing pieces to reconfigure for different occasions. This wasn’t whimsical flexibility. It was calculated design strategy responding to economic and social pressures.

Royal jewelry represented enormous capital investment. Detachable design multiplied the apparent size of a collection without equivalent expenditure. An empress could appear to own multiple configurations when she actually owned fewer cleverly engineered convertible pieces. The technical challenge involved creating attachment mechanisms strong enough for security but refined enough to be invisible.

The solution involved precisely machined pins and receivers hidden within metalwork. Connections used tapered pins fitting into matching receivers, held by friction and sometimes spring-loaded catches. The joins had to be invisible from normal viewing distances while remaining strong enough to resist fabric movement forces during wear.

Repoussé and Chased Detail: Surface as Structure

The metalwork on several stolen pieces features repoussé and chasing, complementary techniques for creating dimensional relief. Repoussé works from the back, hammering metal forward to create raised design. Chasing works from the front, refining details and adding texture.

The technical sophistication appears in how these craftsmen used decorative surface treatment to enhance structural performance. A raised scroll motif creates a curved channel that resists bending better than flat metal of equivalent thickness. A chased leaf pattern adds texture that stiffens the surface through countless micro-bends in the material. The best 19th-century jewelers understood that ornament and structure could be the same thing.

This knowledge rarely appeared in written form. Master jewelers trained apprentices through demonstration. The stolen pieces represent generations of accumulated tactile knowledge frozen into physical form. Skilled metalsmiths can study them and understand not just what the creator made, but how they thought about the material and what their hands knew about working it.

What Happens Next (And Why Recovery Won’t Help)

Four hundred police officers are searching for suspects in what appears to be organized crime. French Culture Minister Rachida Dati hasn’t ruled out an inside job. The practical reality is grimmer than official statements suggest.

High-profile jewel thefts typically follow three paths: ransom attempts, black market sales to private collectors, or destruction for individual gemstone sales. Given the $102 million value and international attention, black market sale seems most likely. Some private vault will gain eight extraordinary pieces that no jeweler or historian will ever access again.

The design knowledge lives in physical objects. You cannot understand articulated joint engineering from photographs. You need to examine actual hinges, measure pin diameters, test flexibility, study wear patterns revealing how pieces moved during 150-plus years of existence. You need to see how Nitot oriented rose-cut diamonds relative to mounting angles, count thickness variations in silverwork, map internal structures that photographs cannot capture.

If these pieces enter a private collection, that knowledge becomes inaccessible. If they’re destroyed for their stones, it’s gone permanently. Either way, the design history disappears.

The Irreplaceable Loss

France declared in 1530 that crown jewels belonged to the state, not the monarch. This transformed jewelry from personal wealth into national heritage. These objects were meant to transcend individual ownership or government financial needs.

But there’s another dimension to the loss. These pieces preserve design and engineering knowledge existing nowhere else. They’re working examples of techniques that apprentice jewelers can study to understand historical metalworking practices. They’re experimental evidence for theories about how 19th-century craftsmen solved specific technical problems. They’re primary sources for understanding jewelry design vocabulary evolution and what those choices meant to the people who created and wore them.

You cannot replace this with insurance money or perfect reproductions. The knowledge lives in the original object’s material history: the tool marks, the wear patterns, the repairs, the evidence of how a master craftsman’s hand moved metal into final form.

The thieves took $102 million in gemstones. They also took 215 years of design history that cannot be recovered from any other source. That loss is permanent in ways most people will never fully grasp until they need information that only those physical objects could provide, and discover there’s nowhere left to look.

The post When Design History Disappears: The Louvre Heist and 215 Years of Lost Jewelry Craftsmanship first appeared on Yanko Design.