A handmade Kumiko panel can stop you in your tracks. The lattice catches light like stained glass without the color, every sliver of wood outlining a pattern that feels part geometry quiz, part meditation aid. Luxury brands charge about 2,700 dollars for a single wall-sized piece, and collectors gladly queue. That price reflects hours of chiseling and perfect millimeter tolerances, but it also keeps Kumiko pinned to galleries and high-end hotels. When a Canadian maker asked, “What if I could just 3-D print one?”, curiosity flipped into a three-month rabbit hole that now lives on my desk in vivid plastic.

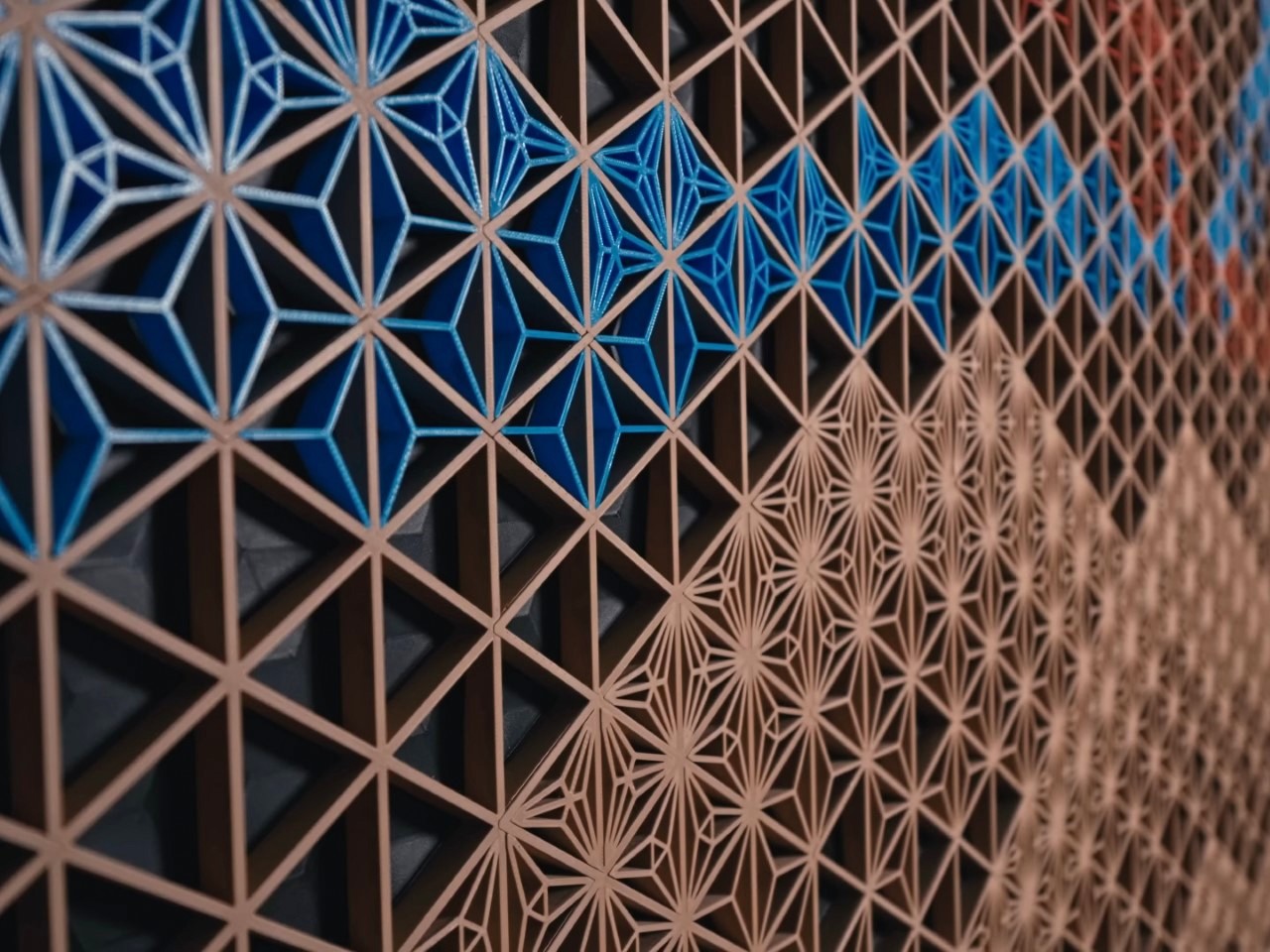

The finished panel looks like a sci-fi portal that wandered through Kyoto. Triangles stack into hexagons, hexagons lock into a field, and a trio of colors pops against a matte black backing. Underneath the gloss sits a spreadsheet of numbers: 48 core panels, 32 inner borders, 32 outer borders, 124 seam covers, and a wild 1,028 patterned inserts. Add 1,650 black backplates, and the printer clock stops at 196 hours with 5,150 grams of filament spent. Material cost hovers near 100 dollars, proof that patience sometimes beats cash.

Designer: Paper View

Kumiko itself dates back to the Asuka period, about thirteen centuries ago, when Japanese carpenters discovered that thin cedar strips could sing in repeated triangles, squares, and diamonds. Artisans today catalog nearly two hundred named patterns, each said to evoke natural scenes: hemp leaves, sea waves, turtle shells. In a traditional workshop, every joint is blunt-fit, no glue, no nails, just wedges nudged until friction pretends to be chemistry. A good panel holds together even after an earthquake test. That purity is part craft and part engineering, which is why the technique feels right at home in the maker sphere.

Shrinking that heritage to a 25 by 25 centimeter print bed required playful geometry. The maker flirted with simple tiles, realized the weak spots, then drilled dovetail sockets straight through the hearts of his hexagons. The dovetail is woodworking’s oldest keystone, and here it reappears in PLA at two millimeters thick, tough enough for studio handling yet forgiving when the cat jumps on the workbench. To expand the sheet horizontally, he mirrored the design at 180 degrees so each print run reaches edge-to-edge, wasting zero nozzle travel. Vertical growth happens inside an L-shaped frame that locks every row, so the panel scales like Lego towers, one clip at a time.

Seams still bothered him. Both woodworkers and cosplayers know that rule #1 of photo day is hiding the line. Rather than slog through sanding and filler, he modeled shallow pockets at every butt joint, then printed thin cover plates that press-fit like sticker tattoos. A final border ring holds sneaky dovetails, so the lattice floats inside a picture frame with only pencil-thin shadows hinting at the joins. Up close, you watch colors melt into a continuous weave; step back, and the eye forgets plastic entirely, reading depth instead of seams.

Eighty hours just for the core tiles, seventy-five more for the colored inserts, and an extra twenty for the black backgrounds that let the colors shout. The filament list reads like a pantry: 2.3 kilograms for panels, 1.8 for inserts, smaller scoops for borders and seams. Each insert is scarcely larger than a postage stamp, yet the panel holds a thousand of them, a reminder that pattern is compound interest for the retinas. The blue-red-beige trio feels playful, but swap those for translucent PETG and you get a window that glows like pixelated rice paper.

The entire parametric file sits on Makerworld, free to tweak. You can stretch the grid to fit a coffee table, compress it into a lampshade, or change every triangle count without opening trigonometry notes. Print the pieces separately, and you can pop out colors next season, or merge the mesh into a single slab so small bits never vanish in the vacuum cleaner. The template even lets you choose a translucent base if you plan to backlight your panel with an LED strip scavenged from your old RGB gaming rig.

Kumiko always balanced precision and poetry, and this printed version stays loyal to both. The machine hum rewrites the chisel rhythm, but the final grid still traps light, guides the gaze, and invites fingertips to trace nested lines. Students looking for a summer project, interior designers hunting for fresh texture, or anyone who loves the thrill of watching an object materialize layer by layer can grab the file tonight and hit start. By next weekend, you might be hanging a slice of centuries-old tradition in neon plastic, proving that elegance sometimes arrives in 0.2-millimeter layers.

The post This Affordable 3D-Printed Kumiko Panel Elevates Your Interiors with Japanese Elegance first appeared on Yanko Design.